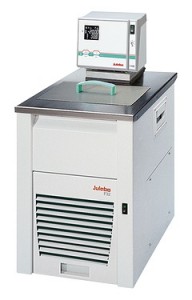

מיכשור תעשייתי - Pure Steam Generator

The PSG pure steam generators consist of a vertical pressure container, in the form of a column divided into two parts. The lower part consists of a tubular heat exchanger, with a double tube sheet (DTS), connected at the top to an expansion chamber or separating column, which allows the steam to flow upwards and prevents water droplets from exiting the chamber To improve the energy efficiency, the preheated water is introduced into a tank with an exchanger, where degassing occurs.

The design of the equipment offers excellent performance for steam production for use in pharmaceutical production:

Sanitary design: Generator designed in the form of a column, with the heat exchanger at the bottom and the expansion chamber above, which guarantees dry and saturated steam, free from droplets, which fall due to the effect of gravity. The impurities are eliminated or intermittently drained from the bottom of the column.

All the active surfaces are mechanically polished to a surface roughness of Ra < 0.6 μm. The exchanger body is also electro-polished after mechanical polishing. All the detachable connections are joined with Tri-Clamp sanitary accessories, and are supplied with FDA approved quality certificates. All welding is carried out in inert gas atmospheres, using an automatic orbital method whenever possible.

Robustness and reliability: The heat exchanger consists of a double tube sheet (DTS), constructed from AISI 316L stainless steel. The column is thermally insulated with rock wool and it is clad with AISI 304 stainless steel sheet. The skid is made out of AISI 304 stainless steel.

Safety and easy operation: Operation is fully automated by means of sensors and the unit is equipped with the required safety and protection equipment, providing warning signals and alarms.

A PLC performs the control and management of the equipment. The equipment can be easily supervised and controlled by means of a touch screen in the control panel.

Quality guarantee: The unit is fully prevalidated in the factory to test its compliance with EN 258 (HTM 2010) standards in terms of saturation, heating and non-condensable gas levels.

Accessories & Options

Pure steam condensation unit for the production of distilled water Energy recovery and degassing system Inlet water and pure steam monitoring Graphical recorder Condenser for sample taking Pressure reducing valve

Applications

Pure steam is mainly used in the pharmaceutical industry and in biotechnology for:

Sterilization. Steam is very efficient for sterilizing due to the double effect produced by the heat of condensation (latent heat transfer) and the humidity generated. Wetting results in cellular wall pore opening and heat cell protein coagulation or denaturalization, which is lethal. Water for injection generation. When the laboratory requires water for injection but in very small amounts, the installation of a pure steam condensing unit for water for injection production can be beneficial. Clean room humidification. Clean steam is sometimes used for clean room humidification by direct injection into the air conditioning system. This theoretically minimises the risk of pollutants entering the production area. The problem with using clean steam for humidifying the air conditioning system of clean rooms is that the clean steam condensate is quite aggressive and may cause corrosion or oxidation in the air conditioning system.

לקבלת הצעת מחיר על מוצר

Pure Steam Generator

לקוח\ה יקר\ה שלום,

נציגינו עומדים לשירותך בכל עת כדי לענות לפנייתך.

לנוחיותך מספר שיטות התקשרות עמנו, על מנת, שנוכל לתת לך את השירות הטוב ביותר:

ליצור קשר באמצעות אי מייל sales@master-cold.co.il או באמצעות מילוי פרטים באתר.

אנא מלא את פרטיך, את נושא הפנייה ואת פרטי ההתקשרות המלאים ואנו נדאג לטפל בפנייתך בכל תשומת הלב ובהקדם האפשרי.

במידה ולא נענית תוך פרק זמן סביר, תוכל\י לברר את סטטוס בקשתך באמצעות קשר טלפוני 1-800-22-22-66

235 קולות, בממוצא

9.1 נקודות מ10 נקודות.

235 קולות, בממוצא

9.1 נקודות מ10 נקודות.